Buena Vista

5-Star Epoxy Flooring of Buena Vista

Connect with us today for trusted residential, business, and industrial epoxy coating services.

Epoxy Floor Finishing Providers in Buena Vista, Oregon

Epoxy floor covering is quick becoming a popular tactic for offering protection to concrete floors.

A durable, low-maintenance finish that can be employed over lots of surfaces, it is easy to see why it has come to be so popular.

In fact, epoxy is swiftly becoming among the most prevalent approach for protecting cement in lots of property and commercial environments. Let’s have a look at a handful of the advantages of epoxy floor surface finish.

To start with, epoxy floor surface finish is great for offering protection to your floor surface versus spots and spills. Whether it’s from coffee drinks, soda pop, or a different liquid, spills are often tough to get rid of.

If they aren’t gotten rid of right now, then they can quickly permeate into the underlying cement providing you a tough issue.

If you have an epoxy finish on your concrete, then spots can be quickly gotten rid of by just sweeping off the location with a broom.

Another advantage of epoxy floor surface finish is that it is non-scratch, dent, and chip resistant. Say goodbye to damaged tiles or sharp edges.

If a spill occurs, simply wipe up the excess liquid quickly and the location will be brought back to its true appearance.

The epoxy sealant also supplies a degree of defense from uv rays. Sunlight can be extremely destructive to painted and stained concrete.

Buena Vista Epoxy Floor Covering Solutions

The many advantages of epoxy floor coverings:

There are lots of advantages to epoxy floor surface finish. If you are considering an epoxy application, then there is no better way to make sure that you get the best outcome possible.

Our certified epoxy specialists will be able to give recommendations on which kinds of resins are appropriate for your particular circumstance, and this insight must be second only to the quality of the resins.

With proper planning, a great finish can last a long time. There is no need to fret about moisture dripping in via a damaged floor surface. In addition, epoxy resins are relatively repair and maintenance free.

Once employed, just wipe up any spills or spots, and you’ll find no need to administer any extra products to ensure their sturdiness.

The advantages of epoxy finishes don’t end there. They can also reduce sound transmission through floors. The barrier produced by the finish can effectively add to the sound reduction by making it more difficult for them to go through the cement.

This has the added in advantage of making noise dampening equipment like radon counters or sump pumps more reliable. These added advantages come at a slightly higher cost, however the outcomes far outweigh the extra cost.

The advantages of epoxy floor surface finish can go even farther than decreasing noise and heat energy transmission. If you are attempting to sell your home or lease a home, the finish can also help to make your home more energy effective.

Less heat energy and less noise signify less electricity costs and less aggravation when attempting to sleep during the night. The finish not only gives protection to your floor surface from grime, but also from pests.

The advantages of epoxy floor surface finish don’t end there. If appropriately employed, they can also produce a non-slip surface area, make your home more safe, and boost the appearance of your home..

With such advantages as these, it’s easy to see why epoxy is becoming such a popular floor surface covering choice. Now is the time to learn more about the process of applying an epoxy floor surface finish to help you choose if this is the best alternative for you.

The first thing we do before we begin any epoxy floor surface finish project is to get rid of any prevailing flooring and coverings. This includes moldings, insulation, and caulk. Oftentimes we may utilize a hard bristled polisher or a power washer to get rid of the old finish and allow it to air dry..

It is necessary that we allow sufficient time for the older finish to totally dry before applying the brand-new one.

Next off, you will need to choose an epoxy floor surface finish kit that will give you the best outcomes. Once you have selected a kit from our team that matches your requirements the first thing our experts do is administer the brand-new finish.

There are 2 different ways to administer an epoxy floor surface finish. One way is to spray it on and allow it to set overnight, then paint over it; the other way is to actually administer it by hand.

Epoxy floor covering is extremely advantageous in domestic and business properties. Get In Touch With our Buena Vista epoxy flooring professionals right now for any questions you have on epoxy finish.

EPOXY FLOOR COATING

If you are considering epoxy floor covering, you will want to check this out. You will discover 5 ways how epoxy floor covering makes your everyday living easy..

This type of floor covering is a strong protective finish that will conserve you cash, time, and energy on upkeep. The cost and hard work before were enormous.

Now, with simply a few standard techniques and a little investigation, you can install a fantastic epoxy floor covering system for a sensible price.

When you look at epoxy floor covering finishes, you will discover the large range of options readily available. There are lots of advantages to picking this type of floor covering..

For instance, if you have an old, scratched, or blemished floor surface, you will find that the resins can help to refresh and offer protection to your floor surface..

This type of floor covering is also very distinct due to the fact that it is comprised of small beads and resins that fit together to produce a strong, smooth floor surface.

One more reason why epoxy floor covering is so appealing is that it is very easy to administer. Our expert installers are able to have the project finished on schedule and efficiently.

When you think of the upkeep of epoxy floor covering, you will understand that it is rather easy to keep it looking great..

Because you can seal the bead together, you will not need to fret about moisture getting in between the sealant and the surface area. If there is any moisture, the sealant will secure it together till it dries out..

You can also utilize the sealant to offer protection to the floor surface versus spills from containers or food products. It is also easy to tidy up if a spill occurs, due to the fact that you do not need to scrub off the dirt with a sponge.

If you wish to know how epoxy floor covering makes your home more valuable, then you should think of sealing your floors..

When you seal the surfaces, you will find that they are much more resilient than typical surfaces. They can deal with much more abuse than common vinyl floors..

This is a fantastic financial investment, and your home will look great for several years to follow.

You may question why the home assessor has recommended epoxy floor covering in your basement..

The sealant will supply extra defense to your home from mold, mustiness, pests, and any other undesirable substance that can trigger damage to your floors..

The sealant will help prevent moisture from developing in between the cement piece and the wood beams in your basement. Minus the sealant, the wood and cement would swell and decay..

This indicates that the sealant will make your basement a lot easier to maintain when compared to many other kinds of floors.

The sealant can supply much more defense than you believe. Sealants can offer protection to your floor surface from degeneration caused by heat, chemicals, moisture, and so much more..

You do not need to fret about the health and wellness of your household when you utilize epoxy floor covering. The sealant does not bring in a level of harmful chemicals to the air as some other floor surface coverings do..

Epoxy surfaces are safe and will not trigger problems for people who are vulnerable to harsh chemicals.

There is no need to invest countless dollars on a brand-new basement floor surface when you can quickly get an epoxy floor surface..

Epoxy surfaces come in a range of colors so you can complement your home’s decoration. An epoxy floor surface can be made with a mixture of various resins to give you a huge variety of alternatives..

If you have hesitations about how epoxy will operate in your home or business property, call our staff today.

We will help you pick the best possible solutions and styles for your epoxy floor covering requirements.

GARAGE FLOOR SURFACE SOLUTIONS

If you are searching for the best floor covering alternatives for garages, our organization will supply you with the details you need.

The garage is one of the most essential rooms in your home.

It is also one of the most abused rooms. For that reason, it is necessary that you offer protection to this valued storeroom.

By picking the best floor covering alternative possible, you can make last a very long time without requiring repairs carried out often.

The leading alternatives for garages are epoxy floor covering, Quikrete garage tile floor covering, and stone floor covering.

Several years of low upkeep and sturdiness make it a fantastic choice for lots of houses. It is immune to spots and has outstanding heat and moisture resistance properties.

It does not yellow quickly and shows off to its finest capability when set up appropriately. It is easy to wash with a power washer and detergent and water solution. It is a perfect choice for a moisture barrier.

The pros of these kinds of floor covering include the fact that they require limited upkeep and can take on any climate change..

They are also resistant to spots. This floor covering item comes in a range of hues and patterns..

Some of the pros of rubber tile floor covering include the fact that it is resistant to spots and heat..

It is easy to manage, and comes in a variety of various color schemes.

The main downside regarding this type of floor covering product is that it might be a bit costlier. This all depends on the style..

The advantages of epoxy sealed concrete floor covering are that it comes with a long life span, it is low upkeep and will require limited to no maintenance in between 6 to ten years.

As you can see from the aforementioned details, all these kinds of floor covering are popular garage floor covering alternatives..

You should do your investigation and determine which type would best fit your requirements. Your budget plan, the appearance of your garage, and the quantity of traffic the garage experiences will all impact your decision..

In the long run, you will invest less cash on epoxy garage floor covering than you will on pricey repairs.

If you choose to utilize epoxy floor covering, you will need to have it sealed.

Rubber tiles are also favored however there are some downsides to these floors also..

One disadvantage of rubber tiles is that they are quickly damaged by acid-based cleaners..

An additional disadvantage of these floors is that they don’t hold up adequately to severe temperatures and dampness..

In the summer these tiles will get hot and sticky and in the cold weather they will split and get damaged..

Epoxy floors conversely are resistant to heat, moisture, and acid and they look great all year long.

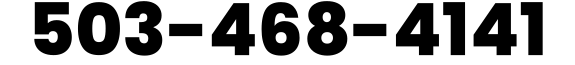

Our team of knowledgeable epoxy flooring pros will give you a free no-obligation quote! Call us today!

Our Epoxy Finshing Work

EPOXY FLOOR SURFACE REPAIR AND FINISHING

If you have recognized an improvement in your floor surfaces or cement driveway after employing an epoxy coating, you probably also recognize a change in its appearance.

This will be in terms of its color, its luster, and even the quantity of dirt it takes on and pulls off. However if you recognize modifications in your flooring that aren’t connected to its application, you may have a more major issue.

That issue is moisture accumulation below the epoxy. This accumulation could be due to improper cleansing methods. Another is a much deeper issue like structural harm, that can trigger your epoxy floor surface coating to peel.

The main reason this happens is because the base material, which is usually either polyurethane or Phenolic resins, is permeable. When it’s applied to a hard surface area like cement, its chemical bonds break up and it’s allowed to gradually penetrate the surface area..

Once this has taken place, the epoxy seeps within the pores of the cement and bonds chemically with the cement itself. Then moisture vaporizes as it reacts with the epoxy. The process creates a physical barrier along the base of the flooring that slows down any further movement.

Moisture vapor is the most significant issue with epoxy flooring coatings. The chemicals bond so firmly that the moisture quickly takes in into the epoxy itself. On top of that, when you put on the epoxy coating to your flooring, you must utilize a special, reinforced flooring scraper to remove it..

And because there are so many other tiny dirt debris, the scraper needs to be used thoroughly to prevent the accumulation from progressing upward and damaging your flooring.

Proper usage of the flooring scraper can prevent your epoxy flooring coatings from ending up being ineffective-and it does not take a lot to make the coatings inadequate.

Proper Seal required

Epoxy coatings can’t appropriately seal if there are too many spaces in the seal. These coatings also need to permit growth and shrinking during the life of the structure, so any gaps in the seal are a potential issue.

Sealing pores and fractures in epoxy coatings also increases the danger of corrosion. The higher the surface area stress of the coating, the more likely it is to wear away in time..

If there are large gaps in the seal, the coating will not be as reliable in containing the rust. Naturally, the larger the surface area gap, the more damage the coating will be able to protect against. That’s why these coatings are only used on larger floors.

Though epoxy floor surface coatings are very resilient, they still have some upkeep requirements. New coatings must be applied every few years, specifically in higher traffic areas.

Some areas are susceptible to consistent traffic and requires to update specific areas in time. This suggests that the coating may become breakable at the spots where it is thinnest. The breakable areas can then chip and get damaged, and all new spots and/or deterioration can then develop.

To conclude, though they are extremely resilient, they must be appropriately maintained in time. They must also be appropriately applied or set up. If the flooring is not sealed correctly, contaminants can build up below..

More recent items are helping make it simpler to install correctly, however if you recognize any problems with your flooring, you should get in touch with our expert installers to make sure that the issue is dealt with before it becomes worse.

Our coverage area

In addition to Buena Vista, we also serve Sidney, Parker, Talbot, Independence, Monmouth, Jefferson, Albany, Lewisville, Marion, Lewisburg and other communities in Polk County.

INDUSTRIAL EPOXY FOR COMMERCIAL PROPERTIES

Why choose industrial-grade epoxy for your business building?

Because this service supplies an excellent series of advantages as follows:

Improved look: Your warehouse does not require a hip and elegant style. Nevertheless, it must still look professional nevertheless. Ease of upkeep and improved appearance.

There is a common mistaken belief among most people about epoxy flooring coatings and their ability to boost the aesthetic appearance of your property.

This mistaken belief is primarily due to the use of lots of chemicals in the cement flooring coatings. That is not the case. While most people assume epoxy flooring coatings are strong and resilient, the truth is epoxy flooring coatings are also extremely versatile.

With proper upkeep and maintenance, you can ensure their long life and appeal for a long time. The chemical representatives in cement flooring coatings diminish gradually in time, providing an attractive surface area that remains clear even after numerous years of consistent usage.

How about their resilience?

As compared to other kinds of floor surfaces solutions, epoxy flooring coatings give a more permanent solution. They are also weather-resistant, which guarantees the resilience and safety of your building.

Their higher degree of resilience and safety is enabled by employing only the right chemical mixture which efficiently seals the surface area while adding to its strength.

Moreover, epoxy flooring coatings are eco-friendly. They don’t add to the already-overloaded ecological pollution and thus help in reducing the negative influence on the environment.

This subsequently assists to protect and maintain the natural resources for a longer period. If this process is appropriately managed, it can significantly reduce the negative influence on the environment. When used appropriately, they can make your location a lot more energy proficient.

Why should you consider epoxy flooring solutions?

The most apparent advantage is the long-lasting savings you can get from utilizing epoxy flooring coatings. Most people only think of the immediate installation costs when conducting a remodeling.

The genuine cost, you’ll face down the road will be the diminishing of the floors and other associated problems. When you utilize epoxy, you can lower your overall costs up by almost 50%.

The additional common advantage of using this sort of floor surfaces is that they supply outstanding flame resistance. The majority of kinds of floor surfaces can quickly sustain fire and some other kinds require specific fireproof materials or procedures to ensure their resilience.

Did you know that this sort of floor surfaces is readily available in various kinds and color schemes? You can pick from a range of epoxy alternatives and add them in your property. By picking this product line, you can conserve cash and time, which can lead you to greater profit.

Besides securing the flooring from dirt and spots, epoxy also assists in avoiding moisture accumulation. This is because the coating keeps your flooring dry..

The epoxy coatings are able to lure moisture far from the surface area. While doing so, gunk and spots can not develop on the flooring’s surface area anymore.

With its resilience, epoxy floor surfaces has the ability to endure severe temperatures. In fact, its resilience permits the floor surfaces to sustain severe cold and heat for an extended period of time..

If you are preparing to put on this product to an industrial warehouse, you are assured that it would endure for several years.

There are lots of additional advantages of employing epoxy in your commercial center or warehouse. Aside from having the ability to avoid moisture accumulation, the epoxy flooring would also be able to boost its life-span..

The more time the epoxy flooring remains protected, the much better it would do the job in helping keep your warehouse well-kept.

WHAT ARE THE VARIOUS KINDS OF EPOXY FLOOR SURFACE COVERINGS?

Epoxy Mortar Floors:

This epoxy flooring is comprised of 100% strong epoxies, graded and/or quartz sand. Mortar systems are able to manage a good deal of impact on the coating The advantages of using this type of epoxy flooring is to help fix fractures before using another type of epoxy flooring.

Spaces to utilize epoxy mortar floors: storage facilities, more business kitchen areas, dining establishment settings, garages, and some production buildings.

Self-Leveling Epoxy Floors:

This form is used to apply over brand-new, outdated, broken, or damaged cement floors. It aids with making a durable, leveled texture and smooth flooring. These type of epoxy floors come in various color options that function very well in commercial, industrial, and property areas.

Ideal areas to utilize self-leveling epoxy floor coverings: storage facilities, big showrooms, business garages, athletic centers, and in kitchen areas also.

Quartz-Filled Epoxy Coating:

Quartz epoxy floor covering is a combination of a high-performance epoxy polymer resin and stained quartz grains. Lots of business and property owners utilize this type of flooring for decorative areas that require hygienic and slip-resistant characteristics.

Common areas to utilize quartz-filled epoxy floors: bathrooms, schools, locker rooms, cafeterias, lobbies, and some showrooms.

Anti-Static Epoxy Covering (Electro-Static Charge Resisting Floors):

These type of epoxy floorings help in reducing any static threats in any kind of job areas. This is extremely essential in areas and spaces which contain flammable content.

The very best locations to utilize anti-static epoxy floors: any type of areas that utilize flammable fuels or liquids, healthcare buildings, electronic, and chemical facilities.

Epoxy Flake Coverings:

This type of epoxy flooring includes tinted flake materials. We insert them in the epoxy to develop a vibrant look. The flakes produce a safer surrounding by helping reduce any slips and falls.

Our epoxy flake floors come in a huge variety of dimensions, colors, styles, and textures. Our specialists can help with tailoring any size area you own.

Most ideal tips to utilize epoxy flake floors: sports plex facilities, surgery centers, garages, and locker rooms.