Cook

5-Star Epoxy Flooring of Cook

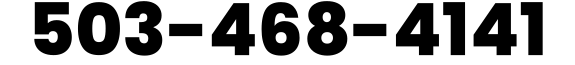

Phone us today for quality home, business, and industrial epoxy coating expertise.

Epoxy Floor Coating Providers in Cook, Oregon

Epoxy floor covering is fast emerging as a popular method for giving protection to concrete floor surfaces.

A durable, low-maintenance coating that may be put on over lots of surface areas, it is simple to see why it has become so well-liked.

In fact, epoxy is quickly emerging as one of the most common technique for protecting concrete in lots of property and commercial environments. Let’s take a look at a handful of the advantages of epoxy floor coating.

Firstly, epoxy floor coating is fantastic for giving protection to your floor against stains and spills. No matter if it’s from coffee drinks, soda, or another liquid, spills are frequently hard to get rid of.

If they aren’t eliminated right now, then they can quickly permeate into the underlying concrete providing you a tough problem.

If you have an epoxy coating on your concrete, then stains can be quickly eliminated by just brushing up the location with a broom.

Yet another benefit of epoxy floor coating is that it is non-scratch, dent, and chip resistant. No more broken tiles or pointed edges.

If a spill happens, simply wipe up the excess liquid rapidly and the location will be restored to its true appearance.

The epoxy sealant also supplies a degree of protection from uv rays. Sunlight can be very destructive to stained and painted concrete.

Cook Epoxy Floor Coating Service

The many advantages of epoxy flooring:

There are lots of advantages to epoxy floor coating. If you are thinking about an epoxy treatment, then there is no better way to make certain that you get the best outcome possible.

Our qualified epoxy professionals will gladly give advice on which kinds of resins are ideal for your particular circumstance, and this guidance ought to be 2nd only to the quality of the resins.

With correct planning, a really good coating can last a long period of time. There is no requirement to worry about moisture dripping in through a damaged floor. Additionally, epoxy resins are fairly repair and maintenance free.

When put on, just wipe up any spills or stains, and you’ll discover no requirement to administer any extra products to ensure their toughness.

The advantages of epoxy finishings do not stop there. They can also reduce sound transmission through floor surfaces. The barrier produced by the coating can really contribute to the sound reduction by making it harder for them to go through the concrete.

This has the added in benefit of making noise dampening devices like radon counters or sump pumps more efficient. These included advantages come at a slightly greater cost, but the results far surpass the additional cost.

The advantages of epoxy floor coating can go even further than lowering sound and heat transmission. If you are attempting to sell off your house or lease an apartment, the coating can also help to make your property more energy effective.

Less heat and less sound mean less electricity costs and less frustration when attempting to sleep at night. The coating not only offers protection to your floor from grime, but also from insects.

The advantages of epoxy floor coating do not stop there. If correctly put on, they can also produce a non-slip surface, make your house more protected, and improve the appearance of your house..

With such advantages as these, it’s simple to recognize why epoxy is emerging as such a preferred floor covering option. Now is the right time to get more information about the process of administering an epoxy floor coating to enable you decide if this is the appropriate choice for you.

The first thing we do before we begin any epoxy floor coating task is to get rid of any existing flooring and coverings. This consists of moldings, insulation, and caulk. Often times we may use a rigid bristled brush or a power washer to get rid of the old coating and enable it to air dry..

It is very important that we enable enough time for the existing coating to completely dry before administering the new one.

Next, you will need to select an epoxy floor coating set that will give you the best results. When you have picked a package from us that fits your requirements the first thing our people do is administer the new coating.

There are two different ways to administer an epoxy floor coating. One way is to spray it on and enable it to set over night, then paint over it; the other way is to actually administer it by hand.

Epoxy floor covering is extremely advantageous in domestic and industrial properties. Phone our Cook epoxy flooring experts now for any type of concerns you have on epoxy coating.

EPOXY FLOOR COATINGS

If you are thinking about epoxy floor covering, you will really want to check this out. You will discover 5 ways how epoxy floor covering makes your everyday living simple..

This type of floor covering is a solid protective coating that will save you money, time, and energy on upkeep. The cost and effort before were massive.

Now, with simply a few fundamental techniques and a little bit of research, you can set up a fantastic epoxy floor covering solution for an affordable price.

When you take a look at epoxy floor covering finishings, you will observe the wide variety of choices readily available. There are lots of advantages to selecting this type of floor covering..

For instance, if you have an older, scratched, or blemished floor, you will discover that the resins can help to revitalize and offer protection to your floor..

This type of floor covering is also really unique since it is comprised of small beads and resins that mesh to produce a solid, seamless floor.

Another reason why epoxy floor covering is so attractive is that it is really simple to administer. Our professional installers can have the task completed on schedule and effectively.

When you think about the upkeep of epoxy floor covering, you will understand that it is quite simple to keep it looking fantastic..

Considering that you can seal the bead together, you will not need to worry about wetness getting between the sealant and the surface. If there is any moisture, the sealant will secure it together up until it dries..

You can also use the sealant to offer protection to the floor against spills from containers or food products. It is also simple to tidy up if a spill happens, since you do not need to scrub off the gunk with a sponge.

If you would like to know how epoxy floor covering makes your house more valued, then you need to think about sealing your floor surfaces..

When you seal the surface areas, you will discover that they are far more durable than regular surface areas. They can deal with far more abuse than typical vinyl floor surfaces..

This is a fantastic investment, and your house will look fantastic for several years to follow.

You may question why the house assessor has recommended epoxy floor covering in your basement..

The sealant will provide additional protection to your house from mold, mildew, termites, and any other undesirable material that can cause harm to your floor surfaces..

The sealant will minimize the risk of wetness from building up between the concrete piece and the wooden beams in your basement. Minus the sealant, the wood and concrete would swell and rot..

This indicates that the sealant will make your basement a lot easier to preserve when compared to many other kinds of floor surfaces.

The sealant can provide far more protection than you believe. Sealants can offer protection to your floor from wear and tear brought on by heat, chemicals, wetness, and more..

You do not need to worry about the health and well-being of your family when you use epoxy floor covering. The sealant does not add a level of toxic chemicals to the air as some other floor coverings do..

Epoxy finishes are non-toxic and will not cause issues for people who are sensitive to severe chemicals.

There is no requirement to invest thousands of dollars on a new basement floor when you can quickly get an epoxy floor..

Epoxy finishes can be found in a range of shades so you can complement your house’s design. An epoxy floor may be produced with a mix of different resins to give you a substantial range of options..

If you have apprehensions about how epoxy will operate in your house or industrial property, contact our organization today.

We will help you choose the best possible services and styles for your epoxy floor covering requirements.

GARAGE FLOOR OPTIONS

If you are searching for the top floor covering options for garages, our team will provide you with the info you need.

The garage is one of the most important rooms in your home.

It is also among the most mistreated rooms. Therefore, it is vital that you offer protection to this valued storeroom.

By selecting the best floor covering choice possible, you can make last a very long time without requiring repair work completed frequently.

The top options for garages are epoxy floor covering, Quikrete garage tile floor covering, and natural stone floor covering.

Several years of low upkeep and toughness make it a fantastic option for lots of homes. It is resistant to stains and has excellent heat and moisture resistance properties.

It does not fade quickly and shows off to its best capability when set up correctly. It is simple to cleanse with a power washer and soap solution. It is an ideal option for a moisture barrier.

The pros of these kinds of floor covering consist of the fact that they require very little upkeep and can handle any climate change..

They are also resistant to stains. This floor covering product comes in a range of color schemes and styles..

Some of the pros of rubber tile floor covering consist of the fact that it is resistant to stains and heat..

It is simple to manage, and comes in a range of different color options.

The primary disadvantage concerning this type of floor covering product is that it may be a bit more expensive. This all depends on the style..

The advantages of epoxy sealed concrete floor covering are that it includes a long life span, it is low upkeep and will require very little to no maintenance between 6 to ten years.

As you can see from the aforementioned info, all these kinds of floor covering are preferred garage floor covering options..

You need to do your research and determine which type would best accommodate your requirements. Your budget, the appearance of your garage, and the quantity of traffic the garage endures will all impact your final decision..

In the long run, you will invest less money on epoxy garage floor covering than you will on expensive repair work.

If you decide to use epoxy floor covering, you will need to have it sealed.

Rubberized tiles are also popular but there are some downsides to these floor surfaces as well..

One disadvantage of rubber tiles is that they are quickly damaged by acid-based cleaning solutions..

An additional disadvantage of these floor surfaces is that they do not stand up well to extreme temperature levels and humidity..

In the summer season these tiles will become hot and sticky and in the winter months they will split and break..

Epoxy floor surfaces on the contrary are resistant to heat, wetness, and acid and they look fantastic all year long.

Our team of knowledgeable epoxy flooring professionals will give you a totally free no-hassle price! Call us now!

Our Epoxy Finshing Projects

EPOXY FLOOR SURFACE REPAIR AND FINISHING

If you have noticed an improvement in your flooring or concrete driveway after applying an epoxy coating, you probably also see a difference in its appearance.

This will be in terms of its color, its shine, and even the quantity of dirt it takes on and takes off. But if you see modifications in your floor that aren’t connected to its treatment, you may have a more severe concern.

That problem is moisture content accumulation beneath the epoxy. This build-up could be due to inappropriate cleansing techniques. Another is a deeper concern like structural harm, that can cause your epoxy floor coating to peel off.

The reason this takes place is due to the fact that the base product, which is normally either polyurethane or Phenolic resins, is permeable. When it’s employed to a hard surface like concrete, its chemical bonds loosen and it’s allowed to gradually penetrate the surface..

When this has taken place, the epoxy permeates in to the pores of the concrete and bonds chemically with the concrete itself. Then moisture vaporizes as it interacts with the epoxy. The process creates a physical barrier around the base of the floor that decreases any additional motion.

Moisture vapor is the most significant problem with epoxy floor finishes. The chemicals bond so closely that the wetness rapidly takes in into the epoxy itself. Additionally, when you put on the epoxy coating to your floor, you must use a specific, enhanced floor scraper to eliminate it..

And due to the fact that there are numerous other tiny dirt fragments, the scraper should be utilized thoroughly to stop the accumulation from progressing upward and damaging your floor.

Appropriate use of the floor scraper can help prevent your epoxy floor finishes from becoming ineffective-and it does not take a lot to make the finishes ineffective.

Appropriate Seal required

Epoxy finishes can not correctly seal if there are too many voids in the seal. These finishes also need to permit expansion and shrinking throughout the lifetime of the structure, so any gaps in the seal are a possible problem.

Sealing pores and cracks in epoxy finishes also boosts the risk of corrosion. The greater the surface stress of the coating, the more probable it is to corrode with time..

If there are big gaps in the seal, the coating will not be as efficient in containing the deterioration. Obviously, the bigger the surface opening, the more damage the coating will be able to protect against. That’s why these finishes are only utilized on bigger floor surfaces.

Though epoxy floor finishes are really durable, they still have some upkeep demands. New finishes must be employed every few years, particularly in higher traffic locations.

Some locations are susceptible to constant traffic and requires to redo particular areas with time. This signifies that the coating may become brittle at the points where it is thinnest. The brittle areas can then split and break, and all new stains and/or damages can then develop.

In conclusion, though they are extremely durable, they must be correctly maintained with time. They must also be correctly employed or set up. If the floor is not sealed correctly, pollutants can buildup beneath..

More recent products are helping make it easier to set up correctly, but if you see any issues with your floor, you need to call our qualified professional installers to make certain that the problem is resolved well before it worsens.

INDUSTRIAL EPOXY FOR COMMERCIAL FACILITIES

Why select industrial-grade epoxy for your industrial property?

Due to the fact that this solution supplies an impressive series of advantages as follows:

Enhanced appearance: Your facility does not require a trendy and sophisticated style. However, it ought to still look sharp at the same time. Ease of upkeep and boosted appearance.

There is a common misunderstanding amongst most people about epoxy floor finishes and their capability to boost the visual appeal of your property.

This misunderstanding is mainly due to the use of lots of chemicals in the concrete floor finishes. That is not the case. While most people assume epoxy floor finishes are tough and durable, the reality is epoxy floor finishes are also extremely flexible.

With correct upkeep and cleansing, you can ensure their prolonged lifespan and charm for a long time. The chemical agents in concrete floor finishes diminish gradually with time, providing an attractive surface that stays clear even after several years of constant use.

How about their durability?

As compared to other types of flooring solutions, epoxy floor finishes give a more irreversible answer. They are also weather-resistant, which makes sure the durability and safety of your building.

Their superior level of durability and safety is made possible by applying only the right chemical mixture which successfully seals the surface while adding to its durability.

Moreover, epoxy floor finishes are environment-friendly. They do not contribute to the already-overloaded environmental pollution and therefore help reduce the negative influence on the earth.

This subsequently helps to preserve and sustain the natural resources for a longer period. If this process is correctly handled, it can considerably reduce the negative influence on the earth. When utilized correctly, they can make your space more energy productive.

Why should you look at epoxy floor solutions?

The most apparent benefit is the long-lasting savings you can obtain from utilizing epoxy floor finishes. Most people only think about the initial setup expenses when doing a remodeling.

The real cost, you’ll face in the future will be the diminishing of the floors and other related damages. When you use epoxy, you can reduce your total expenses up by essentially fifty%.

The additional common benefit of making use of this kind of flooring is that they provide excellent fire resistance. Many kinds of flooring can quickly sustain fire and additional forms require special fire-resistant materials or procedures to ensure their durability.

Did you know that this kind of flooring is readily available in different types and color options? You can choose from a range of epoxy options and install them in your location. By selecting this material, you can save money and time, which can direct you to higher profit.

In addition to securing the floor from dirt and stains, epoxy also helps in avoiding wetness accumulation. This is due to the fact that the coating keeps your floor dry..

The epoxy finishes are able to lure wetness away from the surface. While doing so, gunk and stains can not build up on the floor’s surface anymore.

With its durability, epoxy flooring has the capability to hold up against extreme temperature levels. In reality, its durability allows the flooring to sustain extreme heat and cold for an extended period of time..

If you are planning to put on this product to an industrial warehouse, you are ensured that it would endure for years.

There are lots of additional advantages of applying epoxy in your commercial facility or warehouse. Aside from being able to avoid wetness accumulation, the epoxy floor would also be able to improve its lifespan..

The more time the epoxy floor stays shielded, the better it would work in keeping your warehouse well-kept.

WHAT ARE THE VARIOUS KINDS OF EPOXY FLOOR COVERINGS?

Epoxy Mortar Floors:

This epoxy floor is comprised of one hundred% strong epoxies, graded and/or quartz sand. Mortar systems are able to manage a good deal of effect on the coating The advantages of using this type of epoxy floor is to help fix cracks before using another type of epoxy floor.

Spaces to use epoxy mortar floors: warehouses, more industrial cooking areas, restaurant environments, garages, and various production buildings.

Self-Leveling Epoxy Floors:

This form is utilized to apply over new, outdated, cracked, or damaged concrete floor surfaces. It aids with creating a resilient, leveled surface and sleek floor. These type of epoxy floor surfaces can be found in many different colors that work really well in commercial, industrial, and property spaces.

Greatest spaces to use self-leveling epoxy floor surfaces: warehouses, huge showrooms, industrial garages, athletic facilities, and in cooking areas as well.

Quartz-Filled Epoxy Coating:

Quartz epoxy floor covering is a combination of a high-performance epoxy polymer resin and colored quartz particles. Many industrial and property owners use this type of floor for decorative spaces that require sanitary and slip-resistant characteristics.

Common spaces to use quartz-filled epoxy floors: washrooms, schools, locker rooms, lunchrooms, foyers, and various showrooms.

Anti-Static Epoxy Coating (Electro-Static Charge Resisting Floors):

These type of epoxy floor surfaces help reduce any static risks in any kind of work spaces. This is very important in areas and places which contain flammable components.

The very best locations to use anti-static epoxy floors: any spaces that use flammable fuels or fluids, healthcare buildings, electronic, and chemical spaces.

Epoxy Flake Floors:

This type of epoxy floor contains tinted flake materials. We place them in the epoxy to produce a lively appearance. The flakes produce a safer surrounding by helping reduce any slips and falls.

Our epoxy flake floor coverings can be found in a substantial variety of dimensions, colors, designs, and textures. Our professionals can assist with tailoring any size space you have.

Best recommendations to use epoxy flake floors: sports plex buildings, health care clinics, garages, and locker rooms.