Oak Park

5-Star Epoxy Flooring of Oak Park

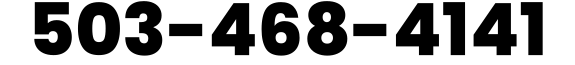

Call us today for trusted residential, commercial, and industrial epoxy coating expertise.

Epoxy Floor Coating Specialists in Oak Park, Oregon

Epoxy floor covering is quickly becoming a popular method for providing protection to concrete floor surfaces.

A resilient, low-maintenance finish that may be applied over many surface areas, it is easy to see why it has become so prominent.

In reality, epoxy is swiftly becoming the most common approach for covering cement in many property and industrial environments. Let’s have a look at a handful of the benefits of epoxy floor finish.

First of all, epoxy floor finish is terrific for providing protection to your floor against spots and spills. No matter if it’s from coffee, soda pop, or a different liquid, spills are often tough to get rid of.

If they aren’t gotten rid of right away, then they can easily leak into the underlying cement providing you a challenging issue.

If you have an epoxy finish on your concrete, then spots can be easily gotten rid of by merely sweeping the location with a broom.

Yet another benefit of epoxy floor finish is that it is non-scratch, dent, and chip resistant. No more damaged tiles or sharp edges.

If a spill takes place, simply wipe up the excess liquid quickly and the location will be brought back to its real look.

The epoxy sealer also provides a degree of security from ultraviolet rays. Sunlight can be exceptionally destructive to stained and painted concrete.

Oak Park Epoxy Floor Covering Service

The various benefits of epoxy flooring:

There are many advantages to epoxy floor finish. If you are thinking about an epoxy treatment, then there is no greater method to make sure that you get the best outcome possible.

Our qualified epoxy experts will be able to deliver recommendations on which types of resins are suitable for your particular circumstance, and this guidance ought to be second only to the quality of the resins.

With correct prep work, a really good finish can last a very long time. There is no need to fret about moisture seeping in through a damaged floor. Additionally, epoxy resins are reasonably maintenance free.

As soon as applied, merely wipe up any spills or spots, and you’ll discover no need to administer any extra products to guarantee their durability.

The benefits of epoxy finishings do not stop there. They can also minimize noise transmission through floor surfaces. The shield created by the finish can effectively add to the sound reduction by making it tougher for them to move through the cement.

This has the added in benefit of making sounds dampening devices like radon counters or sump pumps more effective. These added benefits come at a slightly greater expense, however the outcomes far outweigh the additional expense.

The benefits of epoxy floor finish can go even further than lowering noise and heat transfer. If you are trying to sell off your home or lease a house, the finish can also help to make your residential or commercial property more energy effective.

Less heat and less noise mean less electrical energy bills and less disappointment when trying to sleep during the night. The finish not just offers protection to your floor from dirt, but also from bugs.

The benefits of epoxy floor finish do not stop there. If correctly applied, they can also produce a non-slip surface, make your home more safe, and enhance the look of your home..

With such benefits as these, it’s easy to recognize why epoxy is becoming such a popular floor covering option. Now is the time to find out more about the procedure of employing an epoxy floor finish to enable you decide if this is the right option for you.

The very first thing we do prior to we start any epoxy floor finish job is to get rid of any prevailing flooring and coverings. This consists of moldings, insulation, and caulk. Many times we might utilize a hard bristled brush or a power washer to get rid of the old finish and permit it to air dry..

It is essential that we permit enough time for the existing finish to entirely dry prior to employing the brand-new one.

Next, you will have to choose an epoxy floor finish kit that will offer you the best outcomes. As soon as you have picked a kit from our company that matches your requirements the very first thing our people do is administer the brand-new finish.

There are 2 separate methods to administer an epoxy floor finish. One method is to spray it on and permit it to set overnight, then paint over it; the other method is to actually administer it by hand.

Epoxy floor covering is extremely helpful in residential and business properties. Phone our Oak Park epoxy flooring professionals right now for any kind of concerns you have on epoxy finish.

EPOXY FLOOR COATINGS

If you are thinking about epoxy floor covering, you will really want to check this out. You will find five methods how epoxy floor covering makes your daily living easy..

This kind of floor covering is a strong protective finish that will conserve you money, time, and effort on maintenance. The expense and effort previously were massive.

Now, with simply a couple of basic methods and a little bit of research, you can set up a terrific epoxy floor covering system for a reasonable rate.

When you look at epoxy floor covering finishings, you will observe the large range of options readily available. There are many advantages to selecting this kind of floor covering..

For instance, if you have an older, scratched, or blemished floor, you will discover that the resins can help to revitalize and protect your floor..

This kind of floor covering is also extremely unique since it is made up of small beads and resins that mesh to produce a solid, seamless floor.

Another reason that epoxy floor covering is so attractive is that it is extremely easy to administer. Our expert installers can have the job finished on schedule and efficiently.

When you think about the maintenance of epoxy floor covering, you will recognize that it is rather easy to always keep it looking terrific..

Since you can seal the bead together, you won’t have to fret about wetness getting in between the sealant and the surface. If there is any moisture, the sealant will hold it together up until it dries out..

You can even utilize the sealant to protect the floor against spills from containers or food products. It is also easy to clean up if a spill takes place, since you do not have to clean off the gunk with a sponge.

If you wish to know how epoxy floor covering makes your home more valued, then you ought to think about sealing off your floor surfaces..

When you seal the surface areas, you will discover that they are a lot more resilient than regular surface areas. They can handle a lot more abuse than typical soft top floor surfaces..

This is a terrific financial investment, and your home will look terrific for several years to come.

You might question why the home assessor has advised epoxy floor covering in your cellar..

The sealant will provide additional security to your home from mold, must, termites, and any other unwanted substance that can cause damage to your floor surfaces..

The sealant will defend against wetness from developing in between the cement slab and the wood beams in your basement. In the absence of the sealant, the wood and cement would bloat and rot..

This indicates that the sealant will make your basement much easier to preserve when compared to some other types of floor surfaces.

The sealant can provide a lot more security than you believe. Sealants can protect your floor from degeneration triggered by heat, chemicals, wetness, and so much more..

You do not have to fret about the well being of your household when you utilize epoxy floor covering. The sealant does not bring in a level of harmful chemicals to the air as a few other floor coverings do..

Epoxy surfaces are non-toxic and will not cause problems for individuals who are sensitive to severe chemicals.

There is no need to invest countless dollars on a new basement floor when you can easily get an epoxy floor..

Epoxy surfaces come in a range of color schemes so you can match your home’s design. An epoxy floor may be produced with a mix of different resins to offer you a huge series of alternatives..

If you have uncertainties about how epoxy will operate in your home or business property, contact our company today.

We will help you decide on the best possible options and styles for your epoxy floor covering requirements.

GARAGE FLOOR SEALING

If you are trying to find the best floor covering alternatives for garages, our organization will provide you with the information you require.

The garage is among the most crucial rooms in your house.

It is also one of the most mistreated rooms. Therefore, it is essential that you protect this valued storage room.

By selecting the best floor covering option possible, you can make last a very long time without needing repair work carried out often.

The leading alternatives for garages are epoxy floor covering, Quikrete garage tile floor covering, and stone floor covering.

Several years of low maintenance and durability make it a terrific option for many houses. It is resistant to spots and has excellent heat and moisture resistance properties.

It does not fade easily and shows off to its best potential when installed correctly. It is easy to cleanse with a power washer and a cleaning agent solution. It is an ideal option for a wetness shield.

The pros of these types of floor covering consist of the reality that they require limited maintenance and can handle any climate modification..

They are also resistant to spots. This floor covering product can be found in a range of color or textures and patterns..

A few of the pros of rubberized tile floor covering consist of the reality that it is resistant to spots and heat..

It is easy to maintain, and can be found in a variety of different colors.

The main downside regarding this kind of floor covering product is that it may be a bit pricier. This all depends on the design..

The benefits of epoxy sealed concrete floor covering are that it features a long life expectancy, it is low maintenance and will require limited to no maintenance in between six to 10 years.

As you can see from the above information, all these types of floor covering are favored garage floor covering alternatives..

You ought to do your research and identify which type would best meet your requirements. Your budget, the look of your garage, and the quantity of traffic the garage endures will all affect your decision..

In the long run, you will invest less money on epoxy garage floor covering than you will on costly repair work.

If you decide to utilize epoxy floor covering, you will require to have it sealed.

Rubber tiles are also favored however there are some downsides to these floor surfaces also..

One disadvantage of rubberized tiles is that they are easily harmed by acid-based cleaners..

Another disadvantage of these floor surfaces is that they do not hold up adequately to extreme temperatures and dampness..

In the summer these tiles will become hot and sticky and in the winter months they will fracture and get damaged..

Epoxy floor surfaces on the contrary are resistant to heat, wetness, and acid and they look terrific all year long.

Our group of seasoned epoxy flooring pros will provide you a no-cost no-hassle price! Reach us now!

Our Epoxy Finshing Projects

EPOXY FLOOR SURFACE RESTORATION AND COATING

If you have noticed an enhancement in your flooring or cement driveway after employing an epoxy finish, you probably also recognize a change in its look.

This will be in regards to its color tone, its shine, and even the quantity of dirt it takes on and pulls off. However if you recognize changes in your flooring that aren’t connected to its application, you might have a more severe problem.

That issue is water accumulation underneath the epoxy. This accumulation could be caused by inappropriate cleaning practices. Another is a deeper problem like structural damages, that can cause your epoxy floor finish to peel off.

The reason this happens is because the base material, which is normally either polyurethane or Phenolic resins, is permeable. When it’s added to a hard surface like cement, its chemical bonds break up and it’s empowered to slowly penetrate the surface..

As soon as this has taken place, the epoxy seeps into the pores of the cement and bonds chemically with the cement itself. Then moisture vaporizes as it interacts with the epoxy. The procedure develops a physical shield along the base of the flooring that decreases any additional movement.

Moisture vapor is the biggest issue with epoxy flooring finishings. The chemicals bond so closely that the wetness quickly absorbs into the epoxy itself. In addition, when you employ the epoxy finish to your flooring, you should utilize a specific, enhanced flooring scraper to eliminate it..

And because there are many other microscopic dirt particles, the scraper must be utilized carefully to stop the accumulation from moving upward and damaging your flooring.

Proper usage of the flooring scraper can help prevent your epoxy flooring finishings from ending up being ineffective-and it doesn’t take much to make the finishings inefficient.

Proper Seal required

Epoxy finishings can’t correctly seal if there are too many spaces in the seal. These finishings also need to enable expansion and shrinking throughout the lifespan of the building, so any spaces in the seal are a possible issue.

Sealing pores and cracks in epoxy finishings also raises the danger of deterioration. The greater the surface stress of the finish, the more probable it is to deteriorate with time..

If there are big spaces in the seal, the finish won’t be as effective in containing the corrosion. Naturally, the larger the surface gap, the more damage the finish will be able to prevent. That’s why these finishings are only utilized on larger floor surfaces.

Though epoxy floor finishings are extremely resilient, they still have some maintenance requirements. New finishings should be added every couple of years, especially in high traffic places.

Some areas are susceptible to consistent traffic and requires to update certain locations with time. This suggests that the finish might end up being fragile at the points where it is thinnest. The fragile locations can then split and get damaged, and fresh spots and/or damages can then cultivate.

In conclusion, though they are extremely resilient, they should be correctly maintained with time. They should also be correctly added or installed. If the flooring is not sealed properly, pollutants can build up underneath..

More recent items are making it much easier to set up properly, however if you recognize any problems with your flooring, you ought to call our professional installers to make sure that the issue is addressed before it gets worse.

Our coverage area

In addition to Oak Park, we also serve Hayesville, Four Corners, Keizer, Salem, Fruitland, West Salem, Clear Lake, Lincoln, Bethany, Wheatland and all other places in Marion County.

INDUSTRIAL EPOXY FOR COMMERCIAL PROPERTIES

Why choose industrial-grade epoxy for your business building?

Because this service provides an excellent line of advantages as follows:

Improved appearance: Your facility does not require a hip and stylish design. However, it ought to still look sharp nevertheless. Ease of maintenance and improved look.

There is a popular misunderstanding among the majority of people about epoxy flooring finishings and their ability to boost the aesthetic appearance of your space.

This misunderstanding is primarily caused by using many chemicals in the cement flooring finishings. That is not actually the case. While the majority of people presume epoxy flooring finishings are strong and resilient, the truth is epoxy flooring finishings are also extremely flexible.

With correct maintenance and cleansing, you can guarantee their long life and charm for a very long time. The chemical agents in cement flooring finishings diminish slowly with time, providing an attractive surface that remains crystal clear even after several years of consistent usage.

How about their durability?

As measured up to other types of flooring solutions, epoxy flooring finishings provide a more irreversible answer. They are also weather-resistant, which ensures the durability and safeness of your space.

Their high degree of durability and safeness is enabled by employing just the best chemical mix which successfully seals the surface while adding to its stability.

Simultaneously, epoxy flooring finishings are environment-friendly. They do not add to the already-overloaded ecological pollution and therefore help in reducing the unfavorable effect on the natural environment.

This in turn helps to maintain and sustain the natural resources for a much longer time. If this procedure is correctly managed, it can considerably minimize the unfavorable effect on the natural environment. When utilized correctly, they can make your facility a lot more energy productive.

Why should you look at epoxy flooring solutions?

The most apparent benefit is the long-term savings you can obtain from utilizing epoxy flooring finishings. The majority of people just think about the initial setup expenses when doing a renovation.

The genuine expense, you’ll take on in the future will be the fading of the floors and other associated problems. When you utilize epoxy, you can cut down your overall expenses up by almost 50%.

The other prevalent benefit of using this kind of flooring is that they provide excellent flame protection. Most types of flooring can easily sustain fire and some other types require specific fireproof products or procedures to guarantee their durability.

Did you know that this kind of flooring is readily available in different types and colors? You can choose from a range of epoxy alternatives and install them in your property. By selecting this product, you can conserve money and time, which can lead you to higher revenue.

Aside from securing the flooring from dirt and spots, epoxy also helps in preventing wetness accumulation. This is because the finish keeps your flooring completely dry..

The epoxy finishings have the ability to lure wetness away from the surface. While doing so, dirt and spots can not develop on the flooring’s surface anymore.

With its durability, epoxy flooring has the ability to withstand extreme temperatures. As a matter of fact, its durability permits the flooring to sustain extreme heat and cold for an extended period of time..

If you are preparing to employ this product to an industrial property, you are guaranteed that it would endure for many years.

There are many other benefits of employing epoxy in your industrial facility or warehouse. Other than having the ability to avoid wetness accumulation, the epoxy flooring would also be able to raise its life-span..

The more time the epoxy flooring remains protected, the much better it would work in keeping your property well-kept.

WHAT ARE THE VARIOUS STYLES OF EPOXY FLOOR COATINGS?

Epoxy Mortar Floors:

This epoxy flooring is made up of one hundred% solid epoxies, graded and/or quartz sand. Mortar systems have the ability to handle a great deal of impact on the finish The benefits of using this kind of epoxy flooring is to help fix cracks prior to applying another kind of epoxy flooring.

Areas to utilize epoxy mortar floors: warehouses, more business cooking areas, restaurant environments, garages, and some manufacturing buildings.

Self-Leveling Epoxy Floor Surfaces:

This style is utilized to add over brand-new, outdated, split, or harmed cement floor surfaces. It aids with producing a durable, leveled texture and smooth flooring. These kind of epoxy floor surfaces come in various color tones that work extremely well in commercial, industrial, and property areas.

Ideal areas to utilize self-leveling epoxy floor coverings: warehouses, big showrooms, business garages, athletic centers, and in cooking areas also.

Quartz-Filled Epoxy Covering:

Quartz epoxy floor covering is a mix of a high-performance epoxy polymer resin and colored quartz particles. Numerous business and property managers utilize this kind of flooring for ornamental areas that require hygienic and slip-resistant properties.

Typical areas to utilize quartz-filled epoxy floors: washrooms, schools, locker rooms, snack bars, lobbies, and some showrooms.

Anti-Static Epoxy Covering (Electro-Static Charge Resistant Floors):

These kind of epoxy floors help in reducing any static dangers in any kind of job areas. This is exceptionally crucial in locations and places that contain combustible materials.

The best locations to utilize anti-static epoxy floors: any areas that utilize combustible fuels or liquids, health care buildings, electronic, and chemical facilities.

Epoxy Flake Flooring:

This kind of epoxy flooring contains colored flake products. We place them in the epoxy to produce a vibrant appearance. The flakes create a safe environment by helping reduce any trips and falls.

Our epoxy flake floorings come in a huge variety of sizes, color options, designs, and textures. Our experts can assist with customizing any size space you have.

Most ideal ideas to utilize epoxy flake floors: sports plex facilities, clinics, garages, and locker rooms.