West Salem

5-Star Epoxy Flooring of West Salem

Call us today for quality residential, business, and industrial epoxy flooring expertise.

Epoxy Floor Coating Professioanls in West Salem, Oregon

Epoxy floor covering is fast becoming a popular approach for protecting concrete floors.

A long lasting, low-maintenance finishing that may be employed over numerous surface areas, it is easy to see why it has emerged as so popular.

As a matter of fact, epoxy is rapidly becoming the most prevalent procedure for protecting concrete in numerous property and industrial environments. Let’s have a look at a few of the benefits of epoxy floor surface finishing.

To start with, epoxy floor surface finishing is fantastic for protecting your floor surface versus discolorations and spills. Regardless if it’s from coffee, soda, or a different liquid, spills are typically challenging to eliminate.

If they aren’t eliminated immediately, then they can quickly seep into the underlying concrete offering you a challenging problem.

If you have an epoxy finishing on your concrete, then discolorations can be quickly eliminated by merely brushing up the location with a broom.

Yet another benefit of epoxy floor surface finishing is that it is non-scratch, dent, and chip resistant. Say goodbye to damaged tiles or sharp edges.

If a spill occurs, simply wipe up the excess liquid quickly and the location will be restored to its real appearance.

The epoxy sealant likewise supplies a degree of defense from ultraviolet rays. Sunlight can be exceptionally harmful to stained and painted concrete.

West Salem Epoxy Floor Coating Solutions

The various benefits of epoxy floor coverings:

There are numerous benefits to epoxy floor surface finishing. If you are considering an epoxy treatment, then there is no greater method to ensure that you get the very best outcome attainable.

Our certified epoxy experts will gladly give suggestions on which types of resins are appropriate for your particular circumstance, and this advice must be 2nd only to the quality of the resins.

With proper preparation, a good finishing can last a very long time. There is no requirement to stress over water leaking in through a damaged floor surface. In addition, epoxy resins are reasonably maintenance free.

Once employed, merely wipe up any spills or discolorations, and you’ll discover no requirement to put on any extra products to ensure their resilience.

The benefits of epoxy finishes don’t end there. They can likewise decrease sound transmission through floors. The shield created by the finishing can really add to the sound decrease by making it harder for them to travel through the concrete.

This has the added benefit of making noise dampening devices like radon counters or sump pumps more effective. These included benefits come at a somewhat higher expense, however the results far outweigh the extra expense.

The benefits of epoxy floor surface finishing can go even farther than lowering noise and heat transmission. If you are attempting to sell your home or lease an apartment, the finishing can likewise help to make your property more energy efficient.

Less heat and less noise signify less electrical power expenses and less aggravation when attempting to sleep during the night. The finishing not only protects your floor surface from gunk, but likewise from pests.

The benefits of epoxy floor surface finishing don’t end there. If appropriately employed, they can likewise produce a non-slip surface area, make your home more protected, and improve the appearance of your home..

With such benefits as these, it’s easy to see why epoxy is becoming such a favored floor surface covering option. Now is the time for more information about the process of putting on an epoxy floor surface finishing to help you decide if this is the right option for you.

The first thing we do prior to we start any epoxy floor surface finishing job is to eliminate any prevailing flooring and coverings. This includes moldings, insulation, and caulk. Oftentimes we might utilize a rigid bristled polisher or a power washer to eliminate the old finishing and allow it to air dry..

It is essential that we allow sufficient time for the existing finishing to completely dry prior to putting on the brand-new one.

Thereafter, you will have to select an epoxy floor surface finishing kit that will provide you the very best results. Once you have selected a package from our team that suits your needs the first thing our experts do is put on the brand-new finishing.

There are 2 different ways to put on an epoxy floor surface finishing. One method is to spray it on and allow it to set overnight, then paint over it; the other method is to simply put on it by hand.

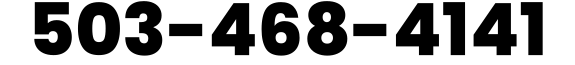

Epoxy floor covering is highly useful in home and business properties. Phone our West Salem epoxy flooring professionals today for any sort of questions you have on epoxy finishing.

EPOXY FLOOR FINISHING

If you are considering epoxy floor covering, you will really want to check this out. You will discover 5 ways how epoxy floor covering makes your everyday living easy..

This type of floor covering is a durable protective finishing that will save you cash, time, and energy on maintenance. The expense and effort previously were huge.

Now, with simply a few standard strategies and a very little homework, you can install an excellent epoxy floor covering solution for an affordable price.

When you look at epoxy floor covering finishes, you will discover the wide variety of choices available. There are numerous benefits to selecting this type of floor covering..

For instance, if you have an old, scratched, or blemished floor surface, you will discover that the resins can help to revitalize and provide protection to your floor surface..

This type of floor covering is likewise extremely unique because it is made up of small beads and resins that fit together to produce a solid, smooth floor surface.

An additional reason epoxy floor covering is so attractive is that it is extremely easy to put on. Our professional installers are able to have the job finished without delay and efficiently.

When you think of the maintenance of epoxy floor covering, you will realize that it is quite easy to keep it looking fantastic..

Since you can seal the bead together, you will not have to stress over moisture getting between the sealant and the surface area. If there is any water, the sealant will secure it together till it dries..

You can even utilize the sealant to provide protection to the floor surface versus spills from containers or food products. It is likewise easy to tidy up if a spill occurs, because you do not have to clean off the gunk with a sponge.

If you need to know how epoxy floor covering makes your home more valued, then you must think of sealing your floors..

When you seal the surface areas, you will discover that they are a lot more resilient than typical surface areas. They can deal with a lot more abuse than typical soft top floors..

This is an excellent financial investment, and your home will look fantastic for several years to come.

You might wonder why the home inspector has advised epoxy floor covering in your basement..

The sealant will supply extra defense to your home from mold, must, pests, and any other undesirable material that can cause damage to your floors..

The sealant will protect against moisture from building up between the concrete piece and the wood beams in your basement. Minus the sealant, the wood and concrete would bulge and decay..

This indicates that the sealant will make your basement a lot easier to maintain when compared to some other types of floors.

The sealant can supply a lot more defense than you believe. Sealants can provide protection to your floor surface from degeneration caused by heat, chemicals, moisture, and so much more..

You do not have to stress over the health and wellness of your family when you utilize epoxy floor covering. The sealant does not add a degree of hazardous chemicals to the air as a few other flooring do..

Epoxy finishes are safe and will not cause issues for individuals who are sensitive to harsh chemicals.

There is no requirement to invest thousands of dollars on a brand-new basement floor surface when you can quickly get an epoxy floor surface..

Epoxy finishes come in a range of color tones so you can match your home’s design. An epoxy floor surface may be produced with a mix of different resins to provide you a big range of alternatives..

If you have uncertainties about how epoxy will work in your home or business property, contact our staff right away.

We will help you pick the very best possible services and designs for your epoxy floor covering needs.

GARAGE FLOOR SURFACE SEALING

If you are searching for the leading floor covering alternatives for garages, our organization will supply you with the details you need.

The garage is one of the most crucial rooms in your house.

It is likewise one of the most mistreated rooms. For that reason, it is imperative that you provide protection to this valued storeroom.

By selecting the very best floor covering option possible, you can make last a long period of time without requiring repair work done typically.

The leading alternatives for garages are epoxy floor covering, Quikrete garage tile floor covering, and natural stone floor covering.

Many years of low maintenance and resilience make it an excellent option for numerous homes. It is immune to discolorations and has exceptional heat and water resistance properties.

It does not yellow quickly and shows off to its best capability when installed appropriately. It is easy to cleanse with a power washer and detergent and water solution. It is an ideal option for a wetness shield.

The pros of these types of floor covering include the truth that they need little maintenance and can handle any environment change..

They are likewise resistant to discolorations. This floor covering item can be found in a range of color schemes and patterns..

Some of the pros of rubberized tile floor covering include the truth that it is resistant to discolorations and heat..

It is easy to preserve, and can be found in a variety of different colors.

The primary drawback concerning this type of floor covering material is that it might be a bit more expensive. This all depends upon the style..

The benefits of epoxy sealed concrete floor covering are that it includes a long life expectancy, it is low maintenance and will need little to no maintenance between six to 10 years.

As you can see from the aforementioned details, all these types of floor covering are preferred garage floor covering alternatives..

You must do your homework and figure out which type would best meet your needs. Your budget plan, the appearance of your garage, and the quantity of traffic the garage endures will all impact your decision..

In the long run, you will invest less cash on epoxy garage floor covering than you will on costly repair work.

If you decide to utilize epoxy floor covering, you will need to have it sealed.

Rubber tiles are likewise favored however there are some downsides to these floors as well..

One disadvantage of rubberized tiles is that they are quickly harmed by acid-based cleaners..

One more disadvantage of these floors is that they don’t stand up very well to severe temperatures and dampness..

In the summertime these tiles will get hot and sticky and in the cold weather they will fracture and break..

Epoxy floors alternatively are resistant to heat, moisture, and acid and they look fantastic all year long.

Our group of epoxy flooring experts will give you a no-cost no-hassle estimate! Contact us today!

Our Epoxy Flooring Work

EPOXY FLOOR SURFACE RESTORATION AND FINISHING

If you have noticed an enhancement in your flooring or concrete driveway after adding an epoxy finishing, you probably likewise observe a change in its appearance.

This will be in terms of its color, its luster, and even the quantity of dirt it takes on and takes off. However if you observe changes in your flooring that aren’t connected to its installation, you might have a more serious concern.

That problem is moisture buildup below the epoxy. This accumulation can be due to inappropriate cleaning practices. Another is a much deeper concern like structural damages, that can cause your epoxy floor surface finishing to peel off.

The main reason this happens is due to the fact that the base product, which is generally either polyurethane or Phenolic resins, is penetrable. When it’s put on to a solid surface area like concrete, its chemical bonds loosen and it’s allowed to gradually permeate the surface area..

Once this has occurred, the epoxy seeps in to the pores of the concrete and bonds chemically with the concrete itself. Then water vaporizes as it interacts with the epoxy. The process produces a physical shield along the base of the flooring that slows down any further motion.

Moisture vapor is the most significant problem with epoxy flooring coverings. The chemicals bond so firmly that the moisture quickly takes in into the epoxy itself. In addition, when you employ the epoxy finishing to your flooring, you should utilize a special, reinforced flooring scraper to remove it..

And due to the fact that there are so many other tiny dirt fragments, the scraper needs to be used thoroughly to stop the buildup from progressing up and harming your flooring.

Proper use of the flooring scraper can prevent your epoxy flooring coverings from ending up being ineffective-and it doesn’t take a lot to make the coverings inadequate.

Proper Seal required

Epoxy coverings can’t appropriately seal if there are a lot of voids in the seal. These coverings likewise need to permit expansion and contraction during the lifespan of the building, so any spaces in the seal are a possible problem.

Sealing pores and fractures in epoxy coverings likewise raises the danger of corrosion. The higher the surface area stress of the finishing, the more probable it is to deteriorate in time..

If there are large spaces in the seal, the finishing will not be as effective in containing the corrosion. Obviously, the larger the surface area hole, the more damage the finishing will have the ability to stop. That’s why these coverings are solely used on larger floors.

Though epoxy floor surface coverings are extremely resilient, they still have some maintenance requirements. New coverings should be put on every few years, particularly in high traffic spots.

Some locations are vulnerable to constant traffic and requires to update particular locations in time. This means that the finishing might end up being breakable at the spots where it is thinnest. The breakable locations can then crack and break, and fresh discolorations and/or damages can then cultivate.

In conclusion, though they are highly resilient, they should be appropriately preserved in time. They should likewise be appropriately put on or installed. If the flooring is not sealed correctly, contaminants can build-up below..

More recent items are helping make it easier to install correctly, however if you observe any issues with your flooring, you must consult with our expert installers to ensure that the problem is resolved long before it becomes worse.

Our service area

In addition to West Salem, we also serve Salem, Four Corners, Keizer, Oak Park, Hayesville, Lincoln, Fruitland, Clear Lake, Independence, Bethel and other communities in Polk County.

INDUSTRIAL GRADE EPOXY FOR COMMERCIAL PROPERTIES

Why select industrial-grade epoxy for your business building?

Due to the fact that this option supplies an impressive line of benefits as follows:

Enhanced look: Your facility does not need a trendy and elegant style. Nevertheless, it must still look professional at the same time. Ease of maintenance and boosted appearance.

There is a popular misunderstanding among many people about epoxy flooring coverings and their capability to increase the visual appearance of your space.

This misunderstanding is mostly due to using numerous chemicals in the concrete flooring coverings. That is not actually the case. While many people assume epoxy flooring coverings are tough and resilient, the fact is epoxy flooring coverings are likewise highly flexible.

With proper maintenance and cleansing, you can ensure their extensive life and beauty for a very long time. The chemical representatives in concrete flooring coverings deplete gradually in time, supplying an appealing surface area that remains crystal clear even after numerous years of constant use.

How about their durability?

As measured up to other kinds of flooring solutions, epoxy flooring coverings provide a more irreversible answer. They are likewise weather-resistant, which makes sure the durability and safety of your space.

Their superior degree of durability and safety is enabled by adding only the right chemical mix which effectively seals the surface area while contributing to its stability.

Moreover, epoxy flooring coverings are eco-friendly. They don’t add to the already-overloaded ecological pollution and therefore help in reducing the unfavorable effect on the ecosystem.

This in turn assists to protect and sustain the natural resources for a much longer period of time. If this process is appropriately handled, it can considerably decrease the unfavorable effect on the ecosystem. When used appropriately, they can make your location even more energy efficient.

Why should you take into consideration epoxy flooring solutions?

The most obvious benefit is the long-lasting cost savings you can get from using epoxy flooring coverings. Most people only think of the initial installation costs when doing an improvement.

The genuine expense, you’ll take on in the future will be the fading of the floors and other associated damages. When you utilize epoxy, you can cut down your overall costs up by nearly 50%.

The other common benefit of making use of this type of flooring is that they supply exceptional flame protection. Most types of flooring can quickly sustain fire and other kinds need specific fire-resistant materials or procedures to ensure their durability.

Did you know that this type of flooring is available in different kinds and colors? You can pick from a range of epoxy alternatives and use them in your property. By selecting this product line, you can save cash and time, which can guide you to greater earnings.

In addition to protecting the flooring from dirt and discolorations, epoxy likewise assists in preventing moisture buildup. This is due to the fact that the finishing keeps your flooring completely dry..

The epoxy coverings have the ability to lure moisture far from the surface area. In the process, gunk and discolorations can not develop on the flooring’s surface area anymore.

With its durability, epoxy flooring has the capability to stand up to severe temperatures. As a matter of fact, its durability allows the flooring to withstand severe cold and heat for a long period of time..

If you are planning to employ this material to an industrial property, you are guaranteed that it would last for several years.

There are numerous other benefits of adding epoxy in your industrial center or warehouse. Aside from having the ability to avoid moisture buildup, the epoxy flooring would likewise have the ability to enhance its life-span..

The more time the epoxy flooring stays protected, the much better it would do the job in helping keep your property well-kept.

WHAT ARE THE DIFFERENT STYLES OF EPOXY FLOOR SURFACE COATINGS?

Epoxy Mortar Floors:

This epoxy flooring is made up of 100% solid epoxies, graded and/or quartz sand. Mortar systems have the ability to manage a great deal of effect on the finishing The benefits of using this type of epoxy flooring is to help repair fractures prior to applying another type of epoxy flooring.

Areas to utilize epoxy mortar floors: warehouses, more business cooking areas, dining establishment environments, garages, and various production buildings.

Self-Leveling Epoxy Floors:

This style is used to apply over brand-new, old, cracked, or harmed concrete floors. It helps with making a durable, leveled surface and smooth flooring. These type of epoxy floors come in various color options that function very well in commercial, industrial, and property spaces.

Best spaces to utilize self-leveling epoxy floors: warehouses, huge showrooms, business garages, athletic centers, and in cooking areas as well.

Quartz-Filled Epoxy Floor Coating:

Quartz epoxy floor covering is a combination of a high-performance epoxy polymer resin and colored quartz grains. Numerous business and property managers utilize this type of flooring for decorative spaces that need sanitary and slip-resistant characteristics.

Typical spaces to utilize quartz-filled epoxy floors: restrooms, academic institutions, locker rooms, lunchrooms, lobbies, and various showrooms.

Anti-Static Epoxy Coatings (Electro-Static Charge Resisting Floors):

These type of epoxy floors help in reducing any static dangers in any job spaces. This is exceptionally crucial in locations and spaces which contain flammable components.

The very best locations to utilize anti-static epoxy floors: any type of spaces that utilize flammable fuels or liquids, healthcare buildings, electronic, and chemical spaces.

Epoxy Flake Flooring:

This type of epoxy flooring contains colored flake materials. We place them in the epoxy to develop a lively look. The flakes make a safer environment by helping in reducing any slips and falls.

Our epoxy flake floors come in a big variety of dimensions, color schemes, styles, and textures. Our experts can assist with customizing any size area you have.

Ideal tips to utilize epoxy flake floors: sports plex buildings, clinics, garages, and locker rooms.